1. What are High Bay and Low Bay Lighting?

The bay lights are an important part of modern industrial lighting. There are the following types: metal halide (MH) lights, high-pressure mercury (HPS/LPS) lights, CFLs, and LED bay lights. High Bay & Low Bay lights are lighting fixtures that are used to illuminate large buildings that have up to 10 ft. tall ceilings. They are widely applied indoor spaces such as factories, processing plants, warehouses, indoor sports fields, and manufacturing facilities. Before bay lights are installed, great consideration has to be given to the following:

- The height of the ceiling in the buildings.

- The frequency of high bay or low bay lights used in the facility.

- The installation methods of the lighting fixtures

2. Differences between High Bay and Low Bay Lights

High bay vs low bay lighting list:

- Installation height

- Application

- Beam angle

- Mounting

Installation Height of Bay Lighting:

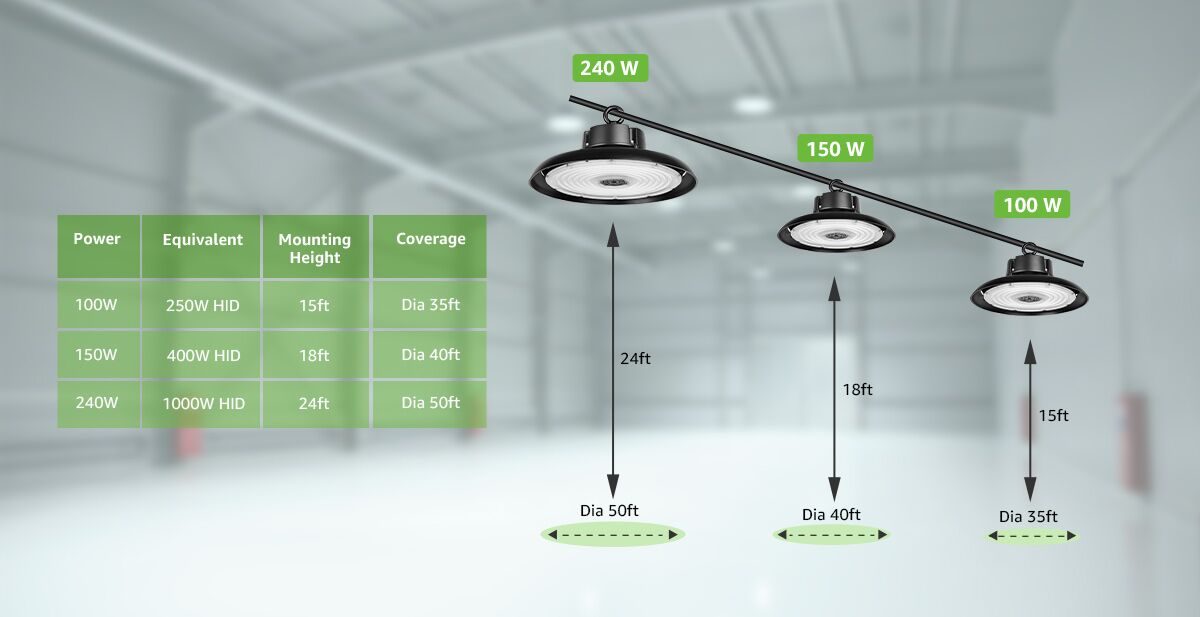

The main difference between high bay lights and low bay lights is the installation height. According to the height of different installation sites, choose the bay light with suitable luminous flux and power, and determine the choice of High bay light or Low bay light. High bay lights are used to illuminate spaces where the ceiling height exceeds 20 ft. And, the luminous flux of these lights is generally above 8000Lm, and the power is generally 250-1000W MH bay lights, or 100-240W LED high bay lights. to operate efficiently from such height, these lights are designed with engineered reflectors (for HPS / MH bulbs) and lens angles (for LED high bays). In the contrast, low bay lights are intended for use in ceilings with heights lower than 20ft, normally between 10ft to 20ft. As such, these lights are mostly used in shops, public buildings, and small retail businesses. the power of these low bay lights is generally 45-85W CFLs or 20-40W LED lights.

Application of High Bays or Low Bays:

High bay lights are used in industrial and commercial spaces. Some areas of application of high bay lights include:

- Storage Facilities

- Factories

- Warehouses

- Airport hangars

- Big manufacturing plants

- Large indoor stadiums

- Gas Stations

Nonetheless, low bay lights can still be employed in these locations, but it’s still worth pointing out that some areas of its application include:

- Frozen Storages

- Retail Stores

- Restaurants

Beam Angle:

A narrow beam angle helps produce a more focused beam, providing high lux levels on the floor. In contrast, a wider beam angle allows large open areas with lower ceiling height to deliver uniform and well-distributed light. High bay lighting uses both narrow and wide beams such as 60°, 90°, and 120°. In meanwhile, low bay lights usually have a beam angle of 120°. For low bay LED lights, lens angles are employed to further spread the light to maintain the desired level of illumination, and the lens angle helps direct the light to a specific location.

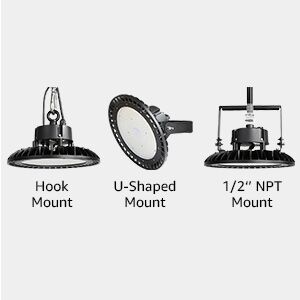

Mounting

Low bay lights are easier to install than high bay lights. And different types of high bay lights are suitable for different installation methods. UFO High bay lighting fixtures can be installed with a hook mount, ceiling mount, and 1/2″NPT mount, while linear high-bays are available for suspension mount, pendant mount, and surface mount.

3. Why LED Multi-bay Lighting is a Good Alternative to Traditional High Bay and Low Bay Lighting

LED bay lighting fixtures provide an excellent cost-effective and energy-efficient alternative to the traditional fluorescent high bay and low bay lights.

Low bay lights are easier to install than high bay lights. And different types of high bay lights are suitable for different installation methods. UFO High bay lighting fixtures can be installed with a hook mount, ceiling mount, and 1/2″NPT National (American) Pipe Thread mount, while linear high-bays are available for hanging mount, 3/4NPT- National (American) Pipe Thread mount, pendant mount, and surface mount.

Traditional high bay lights are equipped with inductive ballasts, which are heavy in weight and low power factor. LED high bay lights are driven by a constant current source and have a high power factor. Compared with LED high bay lights, traditional HPS lights have the disadvantages of slow start-up, flicker, high power consumption, and high noise. MH lights have a short lifetime, flicker, glare, and large power fluctuations.

Led high bay light is generally installed in places with poor environmental conditions such as dust and humidity. In these places with poor environmental conditions, it can work for a long time and reliably. High bay lights have special requirements in terms of structural design, housing, and reflectors. The life of traditional lamps cannot be guaranteed.

Click to find more information about the high bay and low bay lighting differences.